Address

The Lake District, Pune 411048, MH - India

Work Hours

Monday to Friday: 9:30AM - 7PM

Saturday: 10AM - 2PM

It’s important to understand the different types of HR steel products in order to make informed decisions for your project’s needs. Hot rolled steel products are categorized into two distinct groups, each with their own unique production processes and applications. The first type is hot rolled coils, which are manufactured by the process of hot rolling.

This process involves heating up large slabs of steel to incredibly high temperatures and then rolling them out into thinner, longer strips. Hot rolled coils are commonly used in manufacturing construction materials, such as beams, pipes, and hollow structural sections. The second type of hot rolled steel product is hot rolled steel plates, which are made by cutting material from hot rolled coils.

These plates are often used in the construction of large buildings, bridges, and other heavy-duty applications. The hot rolled steel plates are produced from slabs that are created from a continuous casting system, and they are rolled, cooled, and coiled into the sizes required by the customers.

Pickling and Oiling Treatment is used on HR steel to remove impurities and scale from its surface. Acid is used to dissolve the scale and a protective oil coating is applied to prevent corrosion and preserve its quality. This treatment improves the durability and quality of the steel, making it suitable for many industrial uses.

Applications that use hot rolled pickled and oiled steel products include;

This product is mostly used for cold rolling and has the lowest strength among the HR steel products. It has a wide range of applications, ranging from regular machining to drawing and ironing. Additionally, it is used in various cold-rolled products, including CR, GI, EG, and colour-coated plates.

Mild steel, characterized by its low carbon content and relatively soft nature, exhibits a modest tensile strength of up to 340 MPa. Renowned for its excellent elongation and superior formability, this versatile steel finds widespread use across applications ranging from standard to intricate machining tasks. Predominantly employed in automotive parts, mild steel stands out for its adaptability and ease of fabrication.

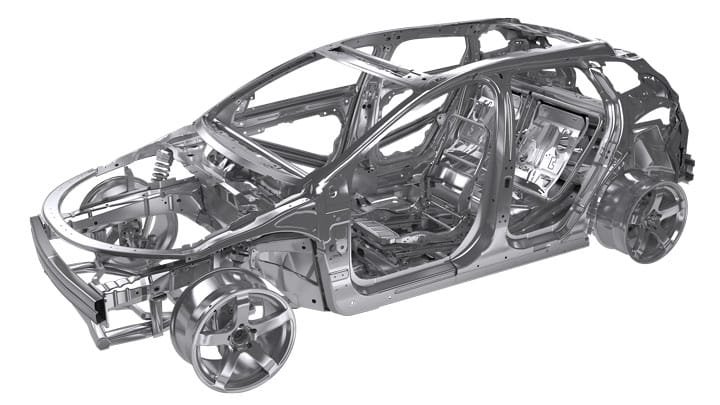

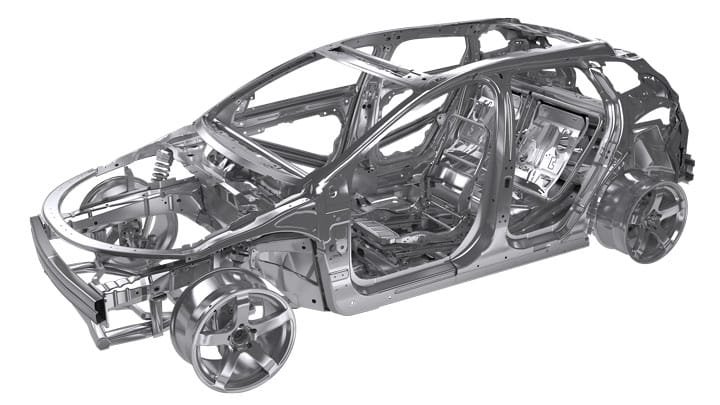

Industry: Automotive Chassis

Hot rolled CQ (commercial quality) Mild steel, characterized by its low carbon content (0.13-0.2%) and tensile strength exceeding 270 MPa, is prominently utilized in automotive chassis components with thicknesses exceeding 1.2 mm. Available in forms such as hot-rolled (HR), pickled and oiled (PO), hot-dip galvanized (HGI), and hot-dip galvannealed (HGA), it serves a variety of manufacturing needs.

Applications:

Commercial Quality automotive and chassis parts

Hot rolled DQ (drawing quality) Mild steel, boasting a low carbon content (0.13-0.2%), achieves a tensile strength exceeding 270 MPa and an elongation of over 33%. This makes it a preferred choice for manufacturing auto chassis parts with thicknesses exceeding 1.2 mm. Available in various forms such as hot-rolled (HR), pickled and oiled (PO), hot-dip galvanized (HGI), and hot-dip galvannealed (HGA), it meets diverse industrial requirements.

Applications

Automotive and chassis parts that require high workability.

Hot rolled DDQ (deep drawing quality) Mild steel, boasting a low carbon content (0.13-0.2%), achieves a tensile strength exceeding 270 MPa and an elongation of over 33%. This makes it a preferred choice for manufacturing auto chassis parts with thicknesses exceeding 1.2 mm. Available in various forms such as hot-rolled (HR), pickled and oiled (PO), hot-dip galvanized (HGI), and hot-dip galvannealed (HGA), it meets diverse industrial requirements.

Applications

Automotive members and chassis parts that require higher workability than grade D hot rolled steel

High-strength steel is engineered by alloying carbon steel with silicon, manganese, nickel, chromium, copper, and other elements to enhance performance beyond standard carbon steel’s 0.2% carbon content. Featuring a tensile strength of approximately 50 kg/mm2, this steel strikes a balance between strength and toughness. It encompasses various types including bake-hardening steel, solid-solution strengthening steel, and precipitation hardening steel. Variant classifications include BH (Bake-Hardenable) steel, HSLA (High Strength Low Alloy) steel, R (Re-phosphorized) steel, IF (Interstitial Free) HSS, and ATOS (AuTOmobile Structural) steel, catering to diverse industrial applications.

High-strength, low-alloy (HSLA) steel is created by adding elements such as Ti and Nb to low-carbon steel to disperse carbonized precipitation into fine grains. Common precipitation elements include NbC, TiC, VC, and AlN. These elements interrupt dislocation motion, which enhances strength and impact toughness. The lesser the precipitation, the higher its strength becomes. The affordability and strength of HSLA steel make it popular as reinforcement for impact toughness in motor vehicles.

Hot rolled A715-40 conforms to ASTM standards, boasting a yield strength surpassing 280 MPa and a tensile strength exceeding 350 MPa. Known for its high yield strength and low elongation, this steel is favored for applications where minimal forming is required.

Applications: Auto chassis parts that require high strength and fatigue resistance, example such as suspensions

Hot rolled A715-50 meets rigorous ASTM (American Society for Testing and Materials) standards, boasting a yield strength exceeding 346 MPa and a tensile strength over 414 MPa. Its combination of high yield strength and low elongation makes it a preferred choice for applications requiring minimal forming.

Applications: Auto chassis parts that require high strength and fatigue resistance, example such as wheels and suspensions parts

Hot rolled A715-55 adheres to ASTM (American Society for Testing and Materials) standards, delivering a yield strength surpassing 380 MPa and a tensile strength exceeding 480 MPa. Its exceptional yield strength coupled with minimal elongation makes it an ideal choice for applications requiring reduced forming.

Applications: Auto chassis parts that require high strength and fatigue resistance, example such as wheels and suspensions parts

Hot rolled A715-60 meets stringent ASTM (American Society for Testing and Materials) standards, offering a yield strength exceeding 410 MPa and a tensile strength surpassing 480 MPa. Its robust yield strength and minimal elongation profile make it highly suitable for applications demanding reduced forming requirements.

Applications: Auto chassis parts that require high strength and fatigue resistance, example such as wheels and suspensions

Hot rolled A715-65 complies with ASTM (American Society for Testing and Materials) standards, boasting a yield strength exceeding 450 MPa and a tensile strength over 520 MPa. Its exceptional yield strength combined with minimal elongation makes it a preferred choice for applications needing minimal forming.

Applications: Auto chassis parts that require high strength and fatigue resistance, example such as the wheels and suspensions parts

Hot rolled A715-70 meets ASTM (American Society for Testing and Materials) standards, offering a yield strength exceeding 500 MPa and a tensile strength over 570 MPa. Its robust yield strength and minimal elongation profile make it highly suitable for applications requiring reduced forming.

Applications: Auto chassis parts that require high strength and fatigue resistance, example such as the wheels and suspensions parts

Hot rolled A715-80 adheres to ASTM (American Society for Testing and Materials) standards, offering an impressive yield strength exceeding 550 MPa, the highest among all hot rolled HSLA steels. It boasts a tensile strength surpassing 620 MPa. Renowned for its superior yield strength and minimal elongation, it is extensively utilized in applications that demand minimal forming.

Applications: Auto chassis parts that require high strength and fatigue resistance, example such as wheels and suspensions parts

Hot rolled 440C exhibits a robust tensile strength exceeding 440 MPa. While American and European customers typically classify steel based on yield strength, counterparts in Asia, including Korea and Japan, prioritize tensile strength for similar categorization. This steel variant is specifically favored for high-strength auto chassis parts, akin to the qualities found in hot rolled A715-xx steels.

Applications: Auto chassis parts that require high strength and fatigue resistance, example such as the wheels and suspensions parts

Hot rolled 540C delivers impressive tensile strength exceeding 540 MPa. While American and European markets typically classify steel by yield strength, Asian markets, including Korea and Japan, prioritize tensile strength for similar categorization. This steel variant is specifically tailored for auto chassis parts demanding even higher strength than those using 440C.

Applications: Auto chassis parts that require high strength and fatigue resistance, example such as wheels and suspensions parts

Hot rolled 590C boasts a robust tensile strength exceeding 590 MPa. In the steel classification, American and European markets traditionally emphasize yield strength, whereas Asian markets, including Korea and Japan, prioritize tensile strength. This specific grade is tailored for auto chassis parts requiring superior strength compared to 540C.

Applications: Auto chassis parts that require high strength and fatigue resistance, example such as the wheels and suspensions parts

Hot rolled 780C delivers an exceptional tensile strength exceeding 780 MPa. In the classification of steel, American and European markets typically prioritize yield strength, while Asian markets, including Korea and Japan, place greater emphasis on tensile strength. This grade stands out as the highest among all hot rolled HSLA steels, making it a prime choice for high-strength auto chassis parts.

Applications: Auto chassis parts that require high strength and fatigue resistance, example such as the wheels and suspensions parts

Crafted by introducing substitutional alloy elements like P and Mn into low-carbon steel, these additions induce lattice deformation and heighten internal stress, inhibiting dislocation movement to enhance overall strength. Typically, substitutional elements offer a more modest strength enhancement compared to interstitial atoms.

Hot rolled 310R offers a robust tensile strength exceeding 310 MPa, tailored for customers seeking superior strength compared to conventional hot rolled steel grades.

Applications: Automotive chassis parts that require a higher strength than hot rolled commercial steel, including members and suspension.

Hot rolled 370R provides a tensile strength of over 370 MPa, thus ideal for auto chassis parts that require higher strength than hot rolled 310R.

Applications: Automotive chassis parts that require a higher strength than hot rolled 310R, including suspensions and others.

Hot rolled 400R provides a tensile strength of over 400 MPa, thus ideal for auto chassis parts that require high strength including members and chassis parts.

Applications: Automotive chassis parts that require a higher strength than hot rolled 370R, including suspensions and others.

Hot rolled 440R provides a tensile strength of over 440 MPa and a yield strength of over 305 MPa. It has the highest tensile strength of all hot rolled R-Class (Rephosphorized) steels.

Applications: Automotive chassis parts that require high strength and fatigue resistance, including suspensions and others.

This is a high-strength hot rolling product consisting of nano-sized precipitates and fine grains with a diameter of 1to 3 μm. It has high tensile strength due to the precipitation strengthening by nano-sized precipitates, and excellent impact resistance and stable fatigue resistance with fine ferrite grains made by recrystallization-controlled rolling. We control the formation of impurities and emulsions in the steel to improve internal quality.

ATOS540 provides a yield strength of over 344 MPa and a tensile strength of over 540 MPa. With good impact toughness and fatigue resistance, it is widely used for structural members in motor vehicles, frames of commercial vehicles and boom arms of heavy-duty equipment.

Applications: Frames of commercial vehicles and crane booms of heavy-duty equipment that require high strength and fatigue resistance

Frames of commercial vehicles and crane booms of heavy-duty equipment that require high strength and fatigue resistance.

Applications: Structural members in motor vehicles, frames of commercial vehicles and boom arms of heavy-duty equipment that require good impact toughness and fatigue resistance

ATOS780 provides a yield strength of over 675 MPa and a tensile strength of over 780 MPa. The steel is widely used for structural members in motor vehicles, frames of commercial vehicles and boom arms of heavy-duty equipment.

Applications: Structural members in motor vehicles, frames of commercial vehicles and boom arms of heavy-duty equipment that require good impact toughness and fatigue resistance

ATOS980 has a yield strength of over 880 MPa and a tensile strength of over 980 MPa, the highest of all hot rolled ATOS products. The steel is widely used for structural members in motor vehicles, frames of commercial vehicles and boom arms of heavy-duty equipment that require ultra-high strength

Applications: Structural members in motor vehicles, frames of commercial vehicles and boom arms of heavy-duty equipment that require ultra-high strength

Advanced high strength steel is categorized as transformation toughened steel, utilizing low-temperature transformation structure. Variants include DP steel, TRIP steel, XF steel, TWIP steel, CP steel, Mart Steel, FB steel, and HB steel. Varieties with a tensile strength of over 1 GPa are giga steel.

Industries: Automotive Chassis

Dual Phase (DP) steel is designed for applications requiring ultra-high strength steel sheets to reduce vehicle weight. Comprising a ferrite matrix and martensite in a two-phase structure, DP steel boasts a low yield ratio of 0.5 to 0.6, making it easy to work with. It offers the second highest elongation after TRIP steel and excellent bake hardening. This is achieved by rapid cooling post-annealing and overaging at temperatures below Ms to prevent hardening.

Hot rolled 590DP offers a yield strength exceeding 305 MPa and a tensile strength over 590 MPa. This makes it perfect for automotive chassis components that demand superior strength.

Applications: Auto chassis parts that require impact toughness, such as suspension, arms and wheel discs

Hot rolled 780DP has a yield strength of over 440 MPa and a tensile strength of over 780 MPa, the highest of all hot rolled DP products

Applications: Auto chassis parts that require high strength and impact toughness, such as suspension, arms and wheel discs

This ferrite-bainite dual-phase steel is engineered for superior hole expansion ratios. The ferrite component ensures excellent elongation, while the bainite provides remarkable flangeability, resulting in exceptional hole expansion. Producing high-quality FB steel involves carefully maintaining hot rolled steel sheets within the ferrite region to create ultra-pure ferrite. Subsequently, solute atoms are concentrated on untransformed austenite before rapid cooling, transforming austenite into bainite. This process ensures the steel’s superior performance and durability.

Hot rolled 440FB steel offers a tensile strength exceeding 440 MPa, making it perfect for automotive chassis parts requiring a high hole expansion ratio (HER) of over 50. This dual-phase steel, composed of ferrite and bainite, ensures minimal hardness variation between the two phases, resulting in an exceptional HER. Its unique composition and properties make 440FB steel an ideal choice for high-performance automotive applications.

Applications: Auto chassis parts that require a high HER, such as arms and wheel discs

Hot rolled 540FB steel is ideal for chassis components demanding a tensile strength exceeding 540 MPa, a yield strength over 355 MPa, and a hole expansion ratio (HER) above 50. This advanced dual-phase steel achieves its enhanced strength through precise control of the size and ratio between ferrite and bainite phases, offering superior performance compared to 440FB. Its optimized composition makes 540FB the preferred choice for high-strength automotive chassis applications.

Applications: Auto chassis parts that require a high HER, such as arms and wheel discs

Hot rolled 590FB steel is the top choice for chassis components requiring a tensile strength above 590 MPa, a yield strength over 420 MPa, and a hole expansion ratio (HER) greater than 50. With the highest HER among hot rolled steels of its class, 590FB is ideal for automotive parts that demand both high strength and exceptional hole expansion capabilities. Its superior performance and durability make it the go-to solution for advanced automotive engineering.

Applications: Auto chassis parts that require high HER, such as suspension, arms and wheel discs

Hot rolled 780FB is ideal for chassis components demanding exceptional tensile strength exceeding 780 MPa and a yield strength of over 540 MPa, combined with a Hole Expansion Ratio (HER) of over 50. As the highest tensile strength hot rolled FB steel, 780FB is extensively utilized in automotive parts where high strength and lightweight properties are crucial.

Applications: Auto chassis components that require high strength and high HER, such as suspension, arms and wheel discs

Hot rolled 780HB (hyper burring) steel is a high-performance single-phase ferritic steel featuring nanosize precipitation. This steel boasts exceptional strength and an impressive hole expansion ratio (HER), attributed to its fine precipitation and absence of coarse, large carbide particles. Unlike other alloys, it avoids red scale by not incorporating silicon, ensuring superior surface quality. Engineered with a low carbon equivalent, 780HB offers excellent weldability, making it a top choice for applications requiring high strength and precision.

Applications: Automobile chassis parts requiring a higher HER than 780HB, such as suspension, arms and wheel discs

This single-phase austenitic steel, characterized by high carbon and manganese content, exhibits deformation twinning during machining, enhancing its strain hardening ratio, strength, and elongation. Microstructure images captured during tensile testing serve as tangible evidence of this deformation twinning phenomenon. The occurrence of twins increases with greater deformation, underscoring the steel’s robust mechanical properties and suitability for demanding applications.

Hot rolled 880TWIP steel boasts a tensile strength exceeding 880 MPa, offering superior strength and elongation compared to conventional hot rolled steel. This makes it an excellent choice for manufacturing wheel and chassis components that demand exceptional formability and durability.

Applications: Auto chassis parts that can help reduce stamping such as lower arms and those with a sophisticated shape, such as styled wheels

This steel comprises a martensitic matrix with traces of bainite or ferrite. Known for its unparalleled tensile strength among carbon steels, it sacrifices ductility for robustness. Optimal enhancement of its yield strength can be achieved through rapid cooling followed by precise tempering.

Hot rolled 1180MART boasts a formidable tensile strength exceeding 1,180 MPa, coupled with a robust yield strength of 900 MPa. This high-performance steel finds application in various industries, including automotive and construction sectors.

Applications: Structural members of commercial vehicles that are subjected to a high load, such as those that require roll forming including bumper beams and door impact beams, and truck frames

Hot rolled 1470M steel offers exceptional tensile strength exceeding 1,470 MPa, augmented by a higher alloy composition compared to 1300MART, enhancing both tensile and yield strength. This advanced steel variant is widely utilized across various applications, including in automotive and structural sectors.

Applications: Structural members of commercial vehicles that are subjected to a high load, such as those that require roll forming including bumper beams and door impact beams, and truck frames

A carbon steel product is classified as high carbon steel if it contains at least 0.30 wt.% carbon or 0.15 wt.% carbon combined with an alloying element for heat treatment. After undergoing final heat treatment, it achieves exceptional strength and hardness. Typical applications include automotive components and industrial machinery parts.

Industries: Automotive Chassis, Machine Structure

Our product range for this application encompasses options for general structures, welding structures, and architectural structures. These products are commonly used in iron frameworks, bridge construction, shipbuilding, and automotive manufacturing.

This product is enhanced with special elements like P, Cu, and Cr to provide superior corrosion resistance across various environments. It is categorized into three types: weather-resistant, sulfuric acid-resistant (from fossil fuel combustion), and seawater-resistant (salt corrosion). This unique formulation is a trademark of POSCO.

This product is classified into three categories: structural steel, pipe steel, and drawing steel. Known for its exceptional weldability and formability, it is widely utilized in architectural structures, pipe piles, gas pipelines, and automotive frameworks.

This steel is specifically designed for drilling in extremely cold regions and deep-sea oil wells. It features high strength, excellent abrasion toughness, and superior corrosion resistance.

This steel is engineered for line pipes transporting crude oil and petrochemical products. It boasts high tensile strength, exceptional low-temperature toughness, hydrogen-induced crack resistance, and excellent weldability. It is categorized into two types: tensile steel, capable of withstanding low temperatures, and sour resistant steel, which offers superior corrosion resistance.

Specifications – Grade

This product is designed for manufacturing high-pressure containers for LPG, acetylene, and other gases. With excellent machinability and pressure resistance, it is ideal for containers with an internal volume of up to 500 liters.

Specifications – Grades

PLATE is the technical and most common term used for HR sheets above 4mm.

Pickled and Oiled HR Coils

Pickled and Oiled HR Sheets

Pickled and Oiled HR Plates

Similar to HR Plates, HRPO Plates are sheets above 4mm, with Pickling and Oiling surface treatment.

Electrical plates, also known as electronic or silicon plates, contain higher silicon content compared to standard steel plates, imparting excellent electric and magnetic properties.

Non-grain-oriented steel exhibits a non-uniform crystal orientation, ideal for products with rotating components like motors and generators. In contrast, grain-oriented steel features a uniform crystal alignment, offering superior magnetic performance suited for stationary applications such as transformers.

With the demand for clean energy solutions escalating to conserve energy and mitigate environmental impact, the demand for electric steel continues to rise.