Address

The Lake District, Pune 411048, MH - India

Work Hours

Monday to Friday: 9:30AM - 7PM

Saturday: 10AM - 2PM

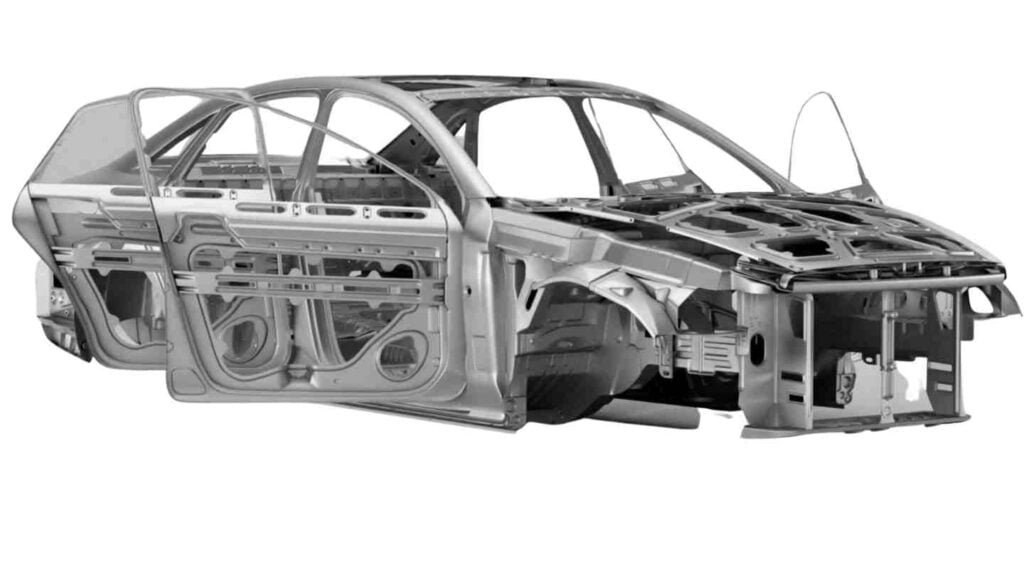

Cold Rolled Steel, ASTM Cold rolled steel, JIS Cold rolled steel, EN cold rolled steel is a highly sought-after material due to its strength, precision, and versatility. It’s formed by passing hot rolled steel through pickling, cold rolling and heat treatment, giving it a smoother, more refined finish. The process results in steel with greater dimensional accuracy, improved surface quality, and exceptional strength characteristics.

Cold rolled steel or Cold Rolled Closed Annealed (CRCA) or cold rolled cold annealed steel is ideal for use in a wide range of applications, including automotive, construction, machinery, and consumer goods. It is suitable for forming, bending, stamping, and welding, and is often used to make components for industries where durability and strength are required. It also has a high resistance to corrosion, making it an ideal material for diverse environments. Its clean, sharp appearance makes it ideal for modern design applications, including furniture, interiors, and fashion accessories.

Mild Steel, characterized by its low carbon content and relatively soft texture, boasts a tensile strength of up to 340 MPa. Its excellent elongation and superior formability make it a preferred choice for a wide range of applications, from everyday uses to advanced machining. The most prevalent application of mild steel is in automotive parts.

Cold rolled steel of commercial quality grades is crafted from low-carbon steels and boasts a tensile strength exceeding 270 MPa. Predominantly utilized for automotive inner components in general drawing processes, these products include CR (Cold Rolled), EG (Electro-Galvanized), GI (Galvanized), and GA (Galvannealed) steels.

Applications: Mechanical Properties

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

Cold-rolled steel drawing quality grade is manufactured as ultra-low carbon steel (Continuous annealing process), has tensile strength of more than 270MPa, and is used for inner parts and outer parts of automotive parts for general drawing processing. Products are CR (Cold Rolled), EG (Electro-Galvanized), GI (Galvanized), and GA (Galvannealed) steels.

Applications: Inner motor vehicle parts that require higher formability than CQ

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

Cold-rolled Deep Drawing Quality steel, produced via the continuous annealing process, is an ultra-low carbon steel with a tensile strength exceeding 270 MPa and an elongation rate of over 36%. This high-performance steel is ideal for both inner and outer automotive components, particularly in deep drawing processes where exceptional surface quality is paramount. Available products include CR (Cold Rolled), EG (Electro-Galvanized), GI (Galvanized), and GA (Galvannealed) steels.

Applications: Inner and outer motor vehicle parts including the rear floor that require high formability.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

Cold-rolled Extra Deep Drawing Quality steel, crafted as an ultra-low carbon steel, boasts a tensile strength exceeding 260 MPa and an elongation rate of over 44%. This steel maintains rigorous surface quality, making it ideal for outer automotive components. Available product variants include CR (Cold Rolled), EG (Electro-Galvanized), GI (Galvanized), and GA (Galvannealed).

Applications: Outer auto parts such as doors and fenders that require high formability and surface quality.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

Cold-rolled Super Extra Deep Drawing Quality (Super-EDDQ) steel, crafted as ultra-low carbon steel, features a tensile strength exceeding 260 MPa and an elongation of over 47%. Ideal for automotive outer parts requiring ultra-deep drawing processing, this steel upholds stringent surface quality standards. Available in CR (Cold Rolled), EG (Electro-Galvanized), GI (Galvanized), and GA (Galvannealed) products.

Applications: Outer auto parts such as side outers that require higher formability and surface quality than EDDQ

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

High-strength cold-rolled steel, known for its deep drawing capabilities and superior strength, is categorized into bake-hardening steel, solid-solution strengthening steel, and precipitation hardening steel. This versatile material includes several variants: BH (bake-hardenable) steel, HSLA (high-strength low-alloy) steel, R (rephosphorized) steel, IF (interstitial free) HSS, ATOS (Automobile Structural) steel, and HB (Hyper Burring) steel.

BH (bake-hardenable) steel is crafted by infusing interstitial elements into extra-low carbon steel and then undergoing a hardening process to enhance yield strength. Initially easy to form, this steel experiences a significant yield strength boost of 30 MPa during the bake-hardening phase. Known for its superior dent resistance compared to commercial quality steel, BH steel retains excellent durability even with reduced thickness.

180YB steel offers a yield strength exceeding 180 MPa, which can further rise to over 210 MPa after baking. This steel is extensively employed for motor vehicle outer panels that demand superior dent resistance and formability, such as hoods and door outers. Available product variants include CR (Cold Rolled), EG (Electro-Galvanized), GI (Galvanized), and GA (Galvannealed) products.

Applications: Outer auto parts that require high dent resistance and formability, such as hoods, doors and fenders

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

210YB steel is perfect for applications demanding higher strength than 180YB. It offers a yield strength exceeding 210 MPa, which can be boosted to over 240 MPa post-bake. Widely utilized for outer automotive parts, 210YB ensures strict surface quality control. Available products include CR (Cold Rolled), EG (Electro-Galvanized), GI (Galvanized), and GA (Galvannealed) products.

Applications: Outer auto parts such as hoods, doors, fenders, etc. that require higher dent resistance than 180YB.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

240YB steel offers a yield strength exceeding 240 MPa, which can be enhanced to over 270 MPa after baking. It is extensively utilized for outer automotive parts, with stringent surface quality control. Available in CR (Cold Rolled), EG (Electro-Galvanized), GI (Galvanized), and GA (Galvannealed) product variants.

Applications: Outer auto parts such as trunks, hoods, doors, fenders, etc. that require higher dent resistance than 210YB

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

270YB steel offers a yield strength exceeding 270 MPa, which can rise to over 300 MPa after the baking process. It belongs in the category of high-strength steel with tensile strength surpassing 390 MPa. Available in various sub-categories including CR (Cold Rolled), EG (Electro-Galvanized), GI (Galvanized), and GA (Galvannealed).

Applications: Inner and outer auto parts such as trunks, hoods, doors, etc. that require high strength and dent resistance.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

High Strength Low Alloy (HSLA) steel is crafted by introducing precipitation-enhancing elements such as Ti and Nb into low carbon steel, fostering carbonized precipitation that disperses into fine grains. Key precipitations like NbC, TiC, VC, and AIN disrupt dislocation movement, enhancing both strength and impact toughness. The smaller the precipitation, the greater the steel’s strength. Renowned for its cost-effectiveness and robust strength, HSLA steel is widely favored in automotive applications to bolster impact resistance.

220YC boasts a yield strength exceeding 220 MPa, primarily serving as a stalwart choice for reinforcing automotive components demanding superior strength. This versatile steel variant encompasses CR (Cold Rolled), EG (Electro-Galvanized), GI (Galvanized), and GA (Galvannealed) categories, catering to diverse industrial needs.

Applications: Automotive reinforcement that is exposed or requires high strength, such as side sills and centre members

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

260YC stands out with a robust yield strength surpassing 260 MPa, making it an optimal choice for reinforcing automotive components demanding higher resilience compared to its 210YC counterpart. This steel variant spans across CR, EG, GI, and GA sub-categories, ensuring versatile application in various industrial settings.

Applications: Automotive reinforcement that is exposed or requires high strength, such as side sills and centre members

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

300YC sets a benchmark with its superior yield strength exceeding 300 MPa, tailored specifically for reinforcing automotive structures that demand greater resilience compared to 260YC. This steel variant spans across CR (Cold Rolled), EG (Electro-Galvanized), GI (Galvanized), and GA (Galvannealed) sub-categories, ensuring versatile application in diverse industrial contexts.

Applications: Automotive reinforcement that is exposed or requires high strength, such as side sills and centre members.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

340YC offers a robust yield strength exceeding 340 MPa, making it ideal for automotive reinforcement applications that demand a high tensile strength of over 410 MPa. Available in CR, EG, GI, and GA sub-categories, this steel variant ensures optimal performance and durability in critical structural components.

Applications: Automotive reinforcement that is exposed or requires high strength, such as side sills and centre members.

Coating:

Uncoated – YES

Electrogalvanized –

Galvanized – YES

Galvannealed – YES

380YC delivers a yield strength exceeding 380 MPa, making it perfect for automotive reinforcements needing a high tensile strength of over 460 MPa. Commonly used in critical structural applications, it is available in sub-categories such as CR, EG, GI, and GA, ensuring superior performance and durability.

Applications: Automotive reinforcement that is exposed or requires high strength, such as side sills and centre members.

Coating:

Uncoated – YES

Electrogalvanized –

Galvanized – YES

Galvannealed – YES

420YC offers a robust yield strength exceeding 420 MPa, ideal for automotive reinforcements that demand a high tensile strength of over 490 MPa. This high-performance steel is available in various sub-categories, including CR, EG, GI, and GA, ensuring optimal versatility and durability for critical applications.

Applications: Automotive reinforcement that is exposed or requires high strength, such as side sills and centre members.

Coating:

Uncoated – YES

Electrogalvanized –

Galvanized – YES

Galvannealed – YES

440YC delivers a tensile strength exceeding 440 MPa, achieved by boosting the content of precipitation-enhancing elements. This enhancement meets the demand for higher strength and weight reduction in motor vehicles. Widely used for automotive reinforcement requiring exceptional strength, 440YC is available in various sub-categories, including CR, EG, GI, and GA.

Applications: Automotive reinforcement that is exposed or requires high strength, such as side sills and centre members.

Coating:

Uncoated – YES

Electrogalvanized –

Galvanized – YES

Galvannealed – YES

Boasting a tensile strength exceeding 590 MPa, 590C stands as the pinnacle of high-strength low alloy (HSLA) steels. It is primarily utilized in automotive reinforcement applications demanding superior strength. Available sub-categories include CR, GI, and GA, ensuring versatility and reliability in meeting stringent automotive standards.

Applications: Automotive reinforcement that is exposed or requires high strength, such as side sills and centre members.

Coating:

Uncoated – YES

Electrogalvanized –

Galvanized – YES

Galvannealed – YES

Produced by incorporating substitutional alloy elements like phosphorus (P) and manganese (Mn) into low carbon steel, this process enhances the steel’s strength. These substitutional elements induce grid deformation and increase internal stress, which disrupts dislocation motion, thereby improving overall strength. Generally, substitutional elements offer a lesser strength enhancement compared to interstitial atoms, but they still play a critical role in bolstering the material’s performance.

With a tensile strength exceeding 340 MPa, 340R is a robust choice for various applications. Its product range includes cold-rolled (CR), electro-galvanized (EG), galvanized (GI), and galvannealed (GA) steel options.

Applications: Inner automotive parts that require high strength, including cowls, wheel aprons and side front members.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

390R delivers a tensile strength exceeding 390 MPa, making it suitable for demanding applications. Available in cold-rolled (CR), electro-galvanized (EG), galvanized (GI), and galvannealed (GA) forms, 390R ensures versatile and reliable performance.

Applications: Inner automotive parts that require high strength, including cowls, wheel aprons and side front members.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

440R stands out with an impressive tensile strength of 440 MPa, marking it as the pinnacle among cold rolled R-Class (rephosphorized) steels. Available in various forms including cold-rolled (CR), electro-galvanized (EG), galvanized (GI), and galvannealed (GA), 440R ensures exceptional performance across diverse applications.

Applications: Inner automotive parts that require high strength, including cowls, wheel aprons and side front members

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

This steel caters specifically to customers seeking enhanced strength for lightweight automotive applications. Achieving exceptional deep drawing capabilities involves incorporating titanium, an oxi-nitrocarburizing element, into ultra-low carbon steel. Meanwhile, high strength is attained through the addition of substitutional elements like phosphorus (P) and manganese (Mn) to ultra-low carbon steel. The inclusion of boron (B) effectively mitigates grain embrittlement risks stemming from phosphorus segregation, ensuring optimal material integrity.

180Y-XR (eXtra R) is tailored for applications demanding superior formability compared to 180YE. Boasting a yield strength surpassing 180 MPa and an elongation exceeding 42 percent, 180Y-XR stands out with minimal interstitial elements {111} and enhanced density for superior insulation performance (R-value). It ranks highest among IF HSS steels in elongation, making it ideal for parts requiring both high strength and deep drawability. Available products encompass CR and GA variants, ensuring versatility across diverse industrial needs.

Applications: Outer auto parts that require high formability, such as side outers.

Coating:

Uncoated –

Electrogalvanized –

Galvanized –

Galvannealed – YES

180YE offers a robust yield strength exceeding 180 MPa and elongation surpassing 34%, catering extensively to applications necessitating high strength and deep drawability. Particularly stringent quality assurance protocols are applied to components intended for exterior use. Product offerings encompass CR, EG, GI, and GA variants, ensuring comprehensive solutions for varied industrial demands.

Applications: Inner and outer auto parts that require high formability, such as doors, fenders and floors

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

220YE delivers a yield strength exceeding 220 MPa and an elongation surpassing 32%, making it a preferred choice for components demanding high strength and deep drawability. Rigorous quality assurance measures are especially applied to components designated for exterior applications. The product lineup encompasses CR, EG, GI, and GA, ensuring comprehensive solutions for diverse industrial needs.

Applications: Inner and outer auto parts that require high formability, such as doors, fenders and floors.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

260YE boasts a yield strength exceeding 260 MPa and a formidable tensile strength surpassing 390 MPa. Its primary application lies in automotive components necessitating exceptional strength. Sub-categories encompass CR, EG, GI, and GA, ensuring versatile solutions across various industrial requirements.

Applications: Inner and outer auto parts that require high formability and high strength, such as doors, fenders and floors.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

300YE delivers a yield strength exceeding 300 MPa and a robust tensile strength surpassing 380 MPa. It finds prominent use in automotive components demanding higher yield strength than 260YE. This grade is available in versatile sub-categories such as CR, EG, GI, and GA, catering to diverse industrial needs with reliability and performance.

Applications: Inner and outer auto parts that require high formability and high strength, such as doors, fenders and floors.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

340E boasts a tensile strength exceeding 340 MPa and an elongation surpassing 32 percent. It is extensively utilized in automotive components requiring high strength and excellent deep drawability. Available in various sub-categories like CR, EG, GI, and GA, 340E ensures superior performance and reliability for diverse industrial applications.

Applications: Inner and outer auto parts that require high formability, such as side outers, doors, fenders and floors

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

340ES features a robust tensile strength exceeding 340 MPa and exceptional elongation over 35 percent, surpassing its predecessor 340E. Primarily employed in intricate automotive parts, it excels in forming sophisticated shapes. Notably, stringent quality controls ensure its reliability, especially for outer part applications. Available in diverse sub-categories such as CR, EG, GI, and GA, 340ES guarantees superior performance across various industrial needs.

Applications: Outer auto parts that require higher formability than 340E, such as side outers and fenders

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

390E boasts a formidable tensile strength exceeding 390 MPa and impressive elongation surpassing 27 percent. It is extensively utilized in automotive parts demanding robust strength and deep drawability capabilities. Rigorous quality standards ensure its suitability for critical applications, particularly in sub-categories such as CR, EG, GI, and GA, catering to diverse industrial requirements.

Applications: Inner and outer auto parts that require high strength and high formability, including members, floors and reinforced A-pillar outers

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

440E exhibits a remarkable tensile strength exceeding 440 MPa and an elongation rate surpassing 27 percent. As the pinnacle of IF HSSs in terms of strength, it is tailored for automotive parts demanding superior durability. Its sub-categories encompass CR, EG, GI, and GA, ensuring comprehensive applicability across various industrial needs.

Applications: Inner and outer auto parts that require high strength and high formability, including members, floors, reinforced A-pillar outers and reinforced floor side rear uppers

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

Advanced High Strength Steel (AHSS) represents a metallurgical marvel, employing low-temperature transformation structures to enhance toughness. Its diverse array includes DP (Dual Phase) steel, TRIP (TRansformation Induced Plasticity) steel, XF (eXtra Formable) steel, TWIP (TWinning Induced Plasticity) steel, CP (Complex Phase) steel, Martensitic Steel, and FB (Ferrite and Bainite) steel. Notably, variants boasting a tensile strength surpassing 1 GPa are branded as Giga Steel, showcasing unprecedented strength for cutting-edge applications in automotive and industrial sectors.

Dual Phase (DP) steel stands as the pinnacle for automotive innovators seeking to lighten vehicle bodies without compromising strength. It marries a ferrite matrix with a martensite phase 2 structure, boasting a low yield ratio of 0.5 to 0.6 that enhances workability. DP steel ranks second in elongation only to TRIP steel, offering exceptional formability. Its rapid cooling post-annealing inverts traditional hardening methods, undergoing overaging at temperatures below Ms to prevent excessive hardening, thus optimizing bake hardening capabilities. This makes DP steel a preferred choice for crafting robust yet lightweight automotive components.

490DP steel offers exceptional tensile strength exceeding 490 MPa, making it an optimal choice for automotive structural components demanding robust performance. Notably resistant to strain aging and characterized by a rigid structure with a yield strength surpassing 270 MPa, it is increasingly favored for lightweight automotive applications. This steel is particularly employed in outer auto parts, which undergo stringent quality assurance protocols. Available in forms such as CR, EG, GI, and GA, it meets diverse production requirements with precision and reliability.

Applications: Automotive structures necessitating exceptional strength, like sill side members and reinforced roof side outers, as well as inner and outer components demanding superior dent resistance such as doors.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

590DP offers a remarkable tensile strength exceeding 590 MPa, making it optimal for high-strength automotive structural components. As the automotive industry increasingly favors lightweight designs, there is a growing interest in utilizing 590DP, which boasts a higher yield strength compared to 490DP, particularly for outer components. These exterior parts are rigorously scrutinized under stringent quality assurance protocols. Available products encompass CR, EG, GI, and GA variants.

Applications: Automotive structures demanding exceptional strength include sill side members and reinforced roof side outers. Components necessitating superior impact toughness encompass side sill side panels and underbody reinforcement components. Additionally, outer parts necessitating dent resistance, like doors, are crucial considerations in automotive design.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized – YES

Galvannealed – YES

780DP boasts a robust tensile strength exceeding 780 MPa, making it a preferred choice for automotive structural components demanding exceptional strength. This steel variant is categorized under CR, GI, and GA subtypes, catering to various application needs in vehicle manufacturing.

Applications: Automotive components demanding exceptional strength encompass sill side members and fortified roof side outer panels, crucial for ensuring structural integrity and safety. Impact members like side sill panels and underbody reinforcement parts require exceptional impact toughness to enhance vehicle durability.

Coating

| Uncoated | Electrogalvanized | Galvanized | Galvannealed |

|---|---|---|---|

| YES | YES | YES |

980DP boasts unmatched tensile strength exceeding 980 MPa, making it the pinnacle among cold rolled DP steels. CGEI STEEL offers 980DP in three tailored variants: 980DP-H for high YR (YS/TS), excellent HER, and bending properties; 980DP-M enhancing welding capabilities; and 980DP-EL prioritizing superior formability. This steel finds applications in CR, GI, and GA products, catering to diverse customer requirements.

Applications:

Coating

| Grade | Uncoated | Electrogalvanized | Galvanized | Galvannealed |

|---|---|---|---|---|

| 980D-M | YES | – | YES | YES |

| 980D-H | YES | – | YES | YES |

| 980D-EL | YES | – | – | – |

This type of steel is engineered to deliver ultra-high strength and exceptional formability, enabling automakers to reduce the weight of car bodies. Essentially, it is a dual-phase alloy comprised of a ferritic matrix, bainite, and residual austenite, often with a small amount of martensite. With a yield ratio ranging from 0.57 to 0.67, TRIP steel offers excellent formability (elongation), making it ideal for components requiring high formability. However, high-strength TRIP steel is rarely used for galvanized applications due to the presence of silicon and other elements that impede plating.

590TRIP offers a remarkable tensile strength surpassing 590 MPa and demonstrates superior elongation compared to HSLA and DP steels of the same tensile strength. Available in CR, EG, and GA variants, it is designed for demanding applications where high strength and enhanced formability are essential.

Applications: Ideal for automotive structural components that demand both high strength and excellent formability, such as floor side panels.

Coating:

Uncoated – YES

Electrogalvanized – YES

Galvanized –

Galvannealed – YES

690TRIP offers exceptional tensile strength exceeding 690 MPa, coupled with an impressive elongation rate of over 21%.

Applications: Ideal for structural components of motor vehicles demanding high strength and superior formability, such as reinforcement tunnels, tunnel hinges, and various structural members.

780TRIP offers a tensile strength exceeding 780 MPa and an elongation surpassing 14%, aligning with VDA 239-100 CR450Y780T standards.

Applications: Ideal for lightweight automotive structural components that demand high strength and superior formability, such as members, reinforcement tunnels, and tunnel hinges.

Coating:

Uncoated – YES

Electrogalvanized –

Galvanized –

Galvannealed –

980TRIP boasts a tensile strength exceeding 980 MPa and an elongation rate surpassing 21%, making it an exceptional choice for advanced automotive applications. This high-strength steel can be intricately shaped using cold rolling processes, positioning it as an ideal substitute for parts traditionally made from 590 MPa steel sheets. The strategic distribution of bainite enhances both elongation and hole expansion ratio (HER), while minimal carbon and phosphorus content improve weldability. Available in CR and GA forms, 980TRIP is engineered to meet the demands of modern vehicle manufacturing.

Applications: 980TRIP steel is tailored for structural components in automobiles that demand both high strength and exceptional formability, crucial for achieving lightweight designs. These include roof side rails, A/B pillar lowers, pillar hinges, and side members, where the material’s robust properties ensure optimal performance in modern vehicle architectures.

Coating:

Uncoated – YES

Electrogalvanized –

Galvanized –

Galvannealed –

1180TRIP steel offers exceptional tensile strength exceeding 1180 MPa and elongation over 14 percent. Engineered to replace high-temperature press-formed steel, it stands as the pinnacle among TRIP steels for automotive applications. This advanced material lineup includes CR, EG, and GA variants, ensuring versatile solutions for high-performance automotive components.

Applications: Engineered for structural components in automotive vehicles demanding high strength and superior formability, such as center pillar uppers, front pillar lowers, and seat belts. These critical parts benefit from the lightweight properties and robust performance of advanced materials.

Coating:

Uncoated – YES

Electrogalvanized –

Galvanized –

Galvannealed –

Engineered for exceptional strength and formability, this steel type is crafted to lighten car bodies significantly. With a remarkable tensile strength multiplied by elongation exceeding 25,000 MPa%, POSCO introduces 980PosM_XF, a CR steel graded at 980 MPa. The manufacturing process involves precise heat treatment, maintaining dual phases of ferrite and austenite, followed by rapid cooling to a tempering temperature. This method ensures the presence of ferrite, martensite, and residual austenite at ambient temperatures, enabling fine crystal grain formation for superior yield strength. The residual austenite is pivotal in achieving elongation rates exceeding 25%.

Applications: High-strength and highly formable structural components, like front pillar uppers, are essential for lightweight motor vehicles.

As a single-phase austenitic steel enriched with high carbon and manganese, this alloy exhibits remarkable deformation twinning during machining. This process enhances its strain hardening ratio, strength, and elongation. Microstructural photos taken during tensile testing vividly illustrate the formation of deformation twins. Increased deformation leads to a higher incidence of these twins.

950TWIP steel boasts an impressive tensile strength exceeding 950 MPa and an elongation surpassing 45%, offering superior strain hardening compared to commercial steel. This makes it ideal for components that demand high energy absorption upon impact.

Applications: Ideal for impact-related motor vehicle components designed to absorb energy, such as bumper beams. Additionally, it excels in automotive parts that demand high formability into complex shapes, like subframes.

Coating:

Uncoated – YES

Electrogalvanized –

Galvanized –

Galvannealed –

This steel targets customers seeking ultra-high strength solutions for enhanced vehicle safety. Composed of ferrite, bainite, martensite, and Ti or Nb precipitates, CP steel undergoes single-phase or dual-phase rolling, involving heating and slow cooling. Predominantly made up of bainite and martensite, it offers a high yield ratio and excellent bending workability.

980CP steel offers a yield strength exceeding 800 MPa and a tensile strength surpassing 980 MPa. Designed for high yield ratio (YS/TS), it is widely utilized in automotive parts requiring excellent impact protection.

Applications: Structural components of motor vehicles, such as sill side panels and underbody reinforcements, are crucial for ensuring high impact safety.

1180CP steel delivers a yield strength exceeding 850 MPa and a tensile strength over 1180 MPa. Its high yield strength combined with excellent bending workability makes it perfect for forming and roll forming applications. This versatile steel is available in cold-rolled (CR), galvanized (GI), and galvannealed (GA) products.

Applications: Structural parts of automobile vehicles that require high impact safety measures, such as sill side panels.

Coating:

Uncoated –

Electrogalvanized –

Galvanized – YES

Galvannealed – YES

1180CP-HE steel boasts higher elongation than 1180CP due to the addition of residual austenite. By incorporating this residual austenite into the CP steel matrix, which consists of ferrite, bainite, and martensite, the TRIP effect is leveraged to enhance elongation.

Applications: Structural parts of automobile vehicles that require high impact safety measures, such as sill side panels.

Coating:

Uncoated –

Electrogalvanized –

Galvanized – YES

Galvannealed – YES

This steel features a martensite matrix with traces of bainite or ferrite, offering the highest tensile strength among all carbon steels, albeit with very low ductility. Rapid cooling followed by precise tempering can significantly enhance its yield strength.

1300MART steel offers an impressive tensile strength exceeding 1,300 MPa and a yield strength of 1,000 MPa. Known for its high strength and limited ductility, it is favored for roll forming applications and as structural members to resist car body deformation upon impact. Available products encompass cold-rolled (CR) and galvanized (GI) variants.

Applications: Impact members of automobile vehicles that require high impact toughness, such as side the sill outers and bumper beams

1470MART steel boasts a robust tensile strength surpassing 1,470 MPa and a yield strength of 1,050 MPa. Enhanced with additional alloy elements compared to 1300MART, it prioritizes superior impact safety. This steel is ideal for structural components that safeguard against car body deformation during collisions. Available in both cold-rolled (CR) and galvanized (GI) forms.

Applications: Impact members of automobile vehicles that require high impact toughness, such as side the sill outers and bumper beams

After plating, our black plates are utilized by customers to fabricate a wide range of containers, including food and powdered milk cans, industrial tubes, two-piece cans, tuna cans, easy-open ends, and butane gas canisters.

Specifications – Grades

This cold-rolled steel is perfectly suited for enamel application, enhancing its heat resistance, abrasion resistance, chemical resilience, surface gloss, and other desirable attributes. Post-enameling, the steel exhibits heightened strength, increased heat and abrasion resistance, along with a distinctive aesthetic finish. It finds widespread use in manufacturing inner and outer panels for home appliances, building walls, kitchen fixtures, bathtubs, and a variety of other applications.

Specifications – Grade