Address

The Lake District, Pune 411048, MH - India

Work Hours

Monday to Friday: 9:30AM - 7PM

Saturday: 10AM - 2PM

Steel is one of the most widely used materials in the world, thanks to its strength, durability, and versatility. But did you know that there are different types of steel, each with its characteristics, advantages, and disadvantages? One of these types is Cold-Rolled steel, which is processed in a special way to enhance its properties and performance. In this blog post explain what CR steel is, how it’s made, and where it’s used in various industries and applications.

Cold-rolled steel, also known as CRS, or cold-rolled sheet, is a type of steel that is processed at room temperature, usually below 170°F (77°C). The steel is first cleaned, then pickling, cold rolling, and heat treatment to remove any impurities and mill scales, it is then passed through a cold mill to relatively reduce its thickness to about 0.2 mm to 2.0 mm which significantly improves its surface finish. The cold rolling process also increases the strength and hardness of the steel but reduces its ductility and weldability. CR steel is highly aesthetic and easily machinable, thus widely used for premium applications in modern society.

Cold-rolled steel is different from hot rolled steel, which is processed at high temperatures, usually above 1,100°F (593°C). The steel is heated until it becomes soft and malleable, and then it is passed through a series of rollers to achieve the desired shape and thickness. The hot rolling process also creates a rough and scaly surface on the steel, which is known as mill scale.

– Surface finish: CR steel has a smooth and shiny surface, while HR steel has a rough and scaly surface.

– Dimensional accuracy: CR steel has tighter dimensional tolerances, while hot rolled steel has more variation and distortion.

– Strength and hardness: Cold-rolled steel has higher strength and hardness, while hot rolled steel has lower strength and hardness.

– Ductility and weldability: Cold-rolled steel has lower ductility and weldability, while hot rolled steel has higher ductility and weldability.

– Cost: CR steel is more expensive than hot rolled steel. This is due to its additional processing and quality control.

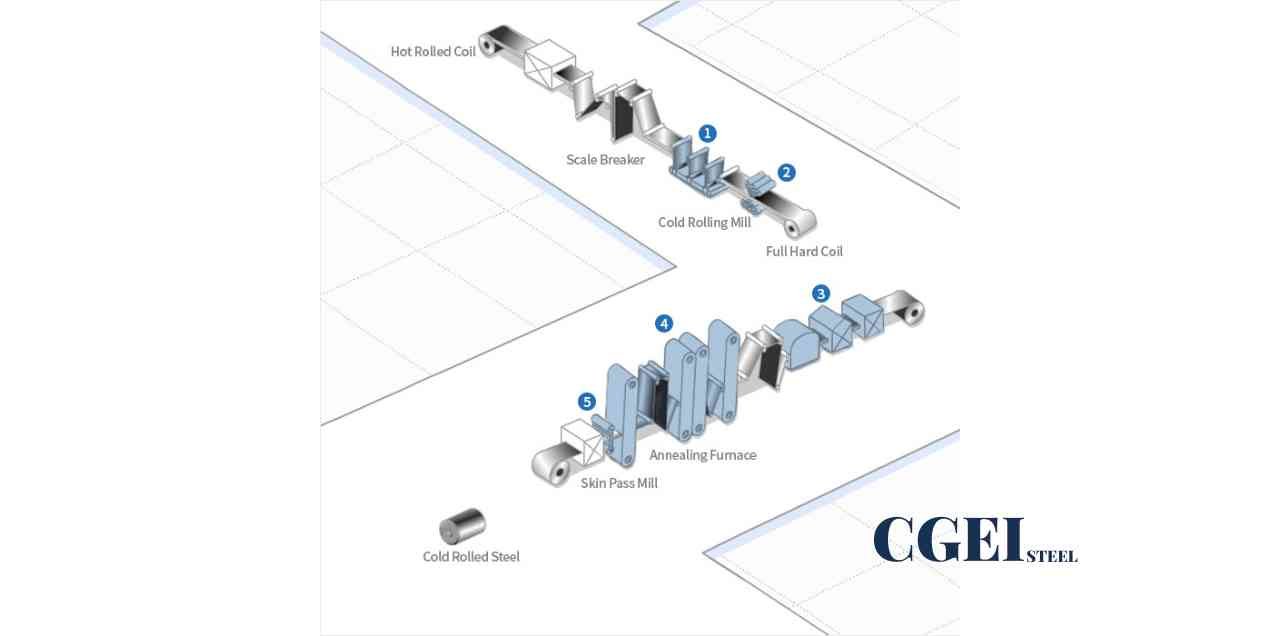

– Cleaning and pickling: The steel is first cleaned and pickled to remove any impurities and mill scale from the surface. Pickling is a metal surface treatment that removes rust and scale from steel and other metals. It involves dipping the metal in a solution of acid, usually hydrochloric or sulfuric, which dissolves the unwanted substances from the surface. The acid solution is called pickle liquor.

– Cold rolling: The steel is then passed through a cold mill, which consists of a series of rollers that apply pressure and tension to the steel. The cold mill reduces the thickness of the steel and improves its surface finish. The cold rolling process also increases the strength and hardness of the steel but reduces its ductility and weldability. The CRS is then coiled or cut into sheets, depending on the desired product.

– Annealing: The cold-rolled steel may undergo annealing, which is a heat treatment process that restores some of the ductility and weldability of the steel. Annealing involves heating the steel to a temperature below its recrystallization point and then cooling it slowly. Annealing relieves the internal stresses and strains caused by cold rolling and softens the steel.

– Tempering: The CRS may also undergo tempering, which is another heat treatment process that modifies the mechanical properties of the steel. Tempering involves heating the steel to a temperature below its annealing point and then cooling it rapidly. Tempering increases the toughness and elasticity of the steel and reduces the brittleness and hardness.

Cold-rolled steel has many applications in various industries and sectors, thanks to its unique properties and advantages. Some of the common uses of CR steel are:

– Construction: Cold-rolled steel is used in construction for framing purposes, such as beams, columns, and sections. It is also used for steel sheds, industrial buildings, and garages. CR steel is preferred for construction because it is light in weight, strong, and easy to ship and assemble.

– Appliances and machinery: Cold-rolled steel is used in appliances and machinery for components that require high precision, excellent surface quality, and good strength, such as metal furniture, washers, dryers, refrigerators, electric fans, and microwave ovens. CR steel is also used for machine parts that must be cut, bent, punched, drilled, and formed.

– Automotive: Cold-rolled steel is used in automotive for parts that require shock-proof and wear-resistant qualities, such as frames, wheels, seat parts, and fuel tanks. CR steel is also used for electric motors, as it has good magnetic properties.

– Pressure vessels: Cold-rolled steel is used in pressure vessels, which are enclosed containers that hold materials under extreme pressure. Pressure vessels are used in petrochemical and nuclear plants, among other industries. CR steel is suitable for pressure vessels because it has a high elongation rate, toughness, embrittlement, and fatigue strength.

CRS is a type of steel that is processed at room temperature to enhance its properties and performance. It has a smooth and shiny surface, high dimensional accuracy, high strength and hardness, low ductility and weldability, and high cost. It is used in various applications that require precision, quality, and strength, such as construction, appliances, machinery, automotive, and pressure vessels.

CR steel is one of the world’s most versatile and widely used materials, and it can meet your specific needs and preferences. If you are looking for high-quality CR steel products, please get in touch with us today.

We are a leading supplier of CRS, and we can provide you with the best service and solutions. Thank you for reading.